Premium Hardware Behind Everyday Fashion

Metal hardware, Bag & Phone Accessories. Built on Technology and Craftsmanship.

Our Story

Rooted in China and serving global markets, Jin Global is a family-owned business with over 20 years of experience in Zamak die casting and hardware manufacturing.

We are dedicated to designing and manufacturing high-end metal accessories, providing an end-to-end solution that covers product development, die casting, and surface finishing. By integrating creative design with refined craftsmanship, we ensure every product perfectly blends functionality with aesthetics.

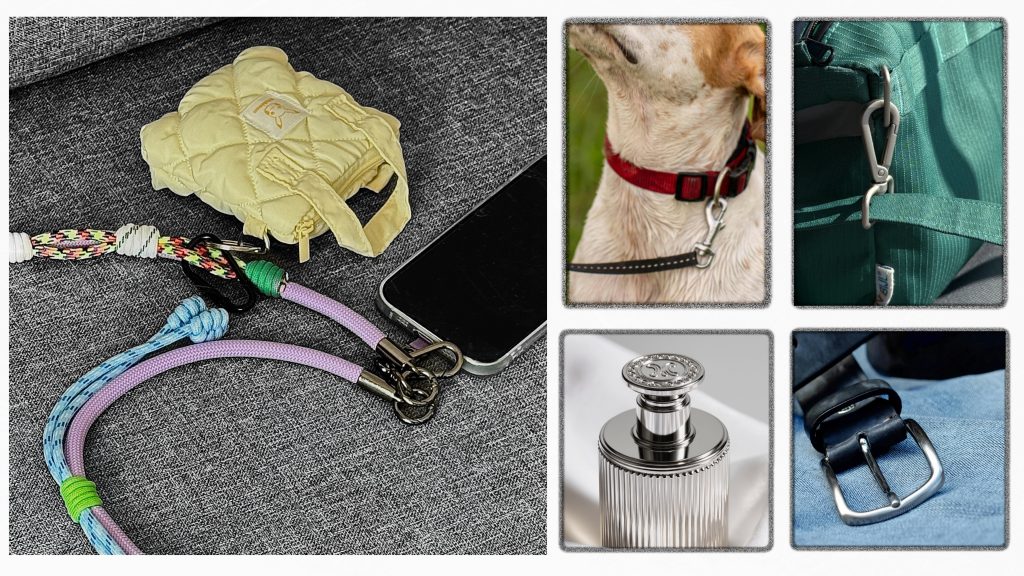

What We Offer

Metal hardware remains at the center of our work. Charms & Straps for Bags & Phones, as well as Zamak Packaging, are natural extensions of our core capabilities.

Leveraging our reliable supply chain and international experience, we deliver solutions that unlock your products’ full potential.

What We Value

- Speed – Fast response, flexible production, and clear communication.

- Transparency – Open processes, honest timelines, and full visibility from quote to delivery.

- Expertise – Two decades of experience turning technical challenges into practical solutions.

Custom Hardware Project

Every project begins with a consultation to understand your product and hardware needs. With 20+ years of experience, we offer practical input on design, function, and production.

After the first call, we begin developing initial designs based on your needs. You can share anything from a rough sketch to a CAD file or physical sample. We’ll take it from there.

Once the initial designs are ready, we create a physical prototype to test dimensions, fit, and function. Depending on the project, we’ll use either 3D printing or traditional mold-making.

Once the sample is validated, we start production. Otherwise, adjustment and resampling will take place until it’s ready for mass production.

Our factory can handle both small-batch orders and large-scale runs, ensuring the same quality and attention to detail every time.

We pack securely and ship worldwide.

We can arrange direct delivery to your location or via partner warehouses for the most efficient route.

Case 1 – Luggage Tracker Case

How we helped a client create a sleek, secure luggage tracker case through 5 rapid prototypes and smart material choices.

Case 2 – Strap Adjuster

Redesigning a tri-glide adjuster into a dual-function quick-release system with improved form and function.

Supply Chain Transparency

Raw Materials

Zamak (Zinc Alloy) is eco-friendly and 100% recyclable.

Responsible Manufacturing

Emissions are filtered, wastewater and byproducts are safely handled by certified third parties.

Surface Finishing

Specialized processes such as electroplating carried out by trusted partners. Regular reviews ensure compliance with environmental and safety standards.

Worker Safety & Compliance

We are committed to a safe and fair workplace. Our operations follow local labor regulations, with ongoing improvements in worker safety and compliance.

Quality Control & Delivery

Multi-step testing before shipment, ensuring compliance with regulations such as REACH and RoHS. Products are packed responsibly and shipped worldwide, ensuring they arrive safely and reliably.