Step 1: Consultation

Every project begins with a consultation to understand your product and hardware needs.

With 20+ years of experience, we offer practical input on design, function, and construction.

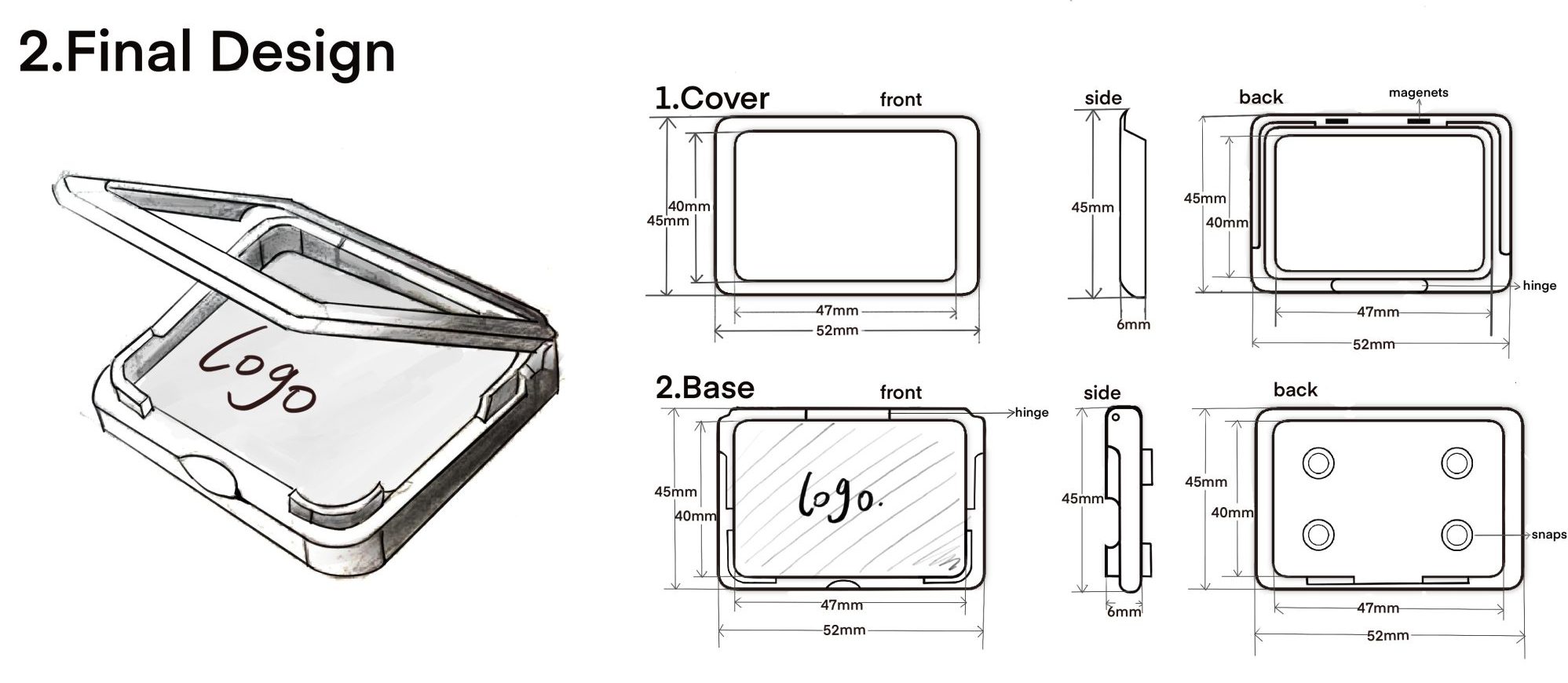

Step 2: Initial Designs

After the first call, we begin developing initial designs based on your needs.

You can share anything from a rough sketch to a CAD file or physical sample — we’ll take it from there.

Step 3: Prototyping

Once the initial designs are ready, we create a physical prototype to test dimensions, fit, and function.

Depending on the project, we’ll use either 3D printing or traditional mold-making.

Step 4: Final Samples

If the sample is right, we start production.

If not, we adjust and resample until it’s ready for mass production.

Step 5: Production

With the final sample approved, we begin production.

Our factory can handle both small-batch orders and large-scale runs, ensuring the same quality and attention to detail every time.

Step 6: Delivery

We pack securely and ship worldwide.

We can arrange direct delivery to your location or via partner warehouses for the most efficient route.